Lowering error rates is essential for every manufacturing business. In the medical device sector, however, the consequences of errors are particularly steep. Mistakes here easily can escalate to severe outcomes, such as failing to meet regulatory standards and causing harm to patients, which subsequently result in expensive and reputation-damaging legal actions.

Implementing training videos that focus on the various factors leading to assembly mistakes is a highly effective strategy to minimize error rates (and thus boost production yields).

LightVision Media Group has over a decade of experience closely working with industry leaders and their R&D, engineering, production, and training teams to help them evaluate production processes, address any inconsistencies, and deliver the best training videos that significantly improve yields.

This article will delve into how such training videos can help in reducing error rates in the production of medical devices.

The Complexity of Medical Device Manufacturing

Unfortunately, conventional training techniques, like manuals and one-on-one instruction, often fail to adequately communicate the complexities of medical device design and production processes.

A study conducted by the Institute of Manufacturing revealed that 83% of manufacturers acknowledge skill gaps among their employees, attributing these to insufficient training. These deficiencies lead directly to elevated error rates, as workers may not comprehend, remember, or correctly interpret manufacturing protocols.

The global medical device market is anticipated to grow to $657 billion by 2028, with a compound annual growth rate (CAGR) of 5.0% starting from 2021. With advancements in artificial intelligence, there is potential for an even faster growth rate.

As the industry expands, so does the complexity of medical devices and their manufacturing processes. Overcoming these challenges demands a highly skilled workforce that is capable of executing intricate tasks with minimal errors.

The Impact of Errors in Medical Device Production

Errors in medical device production might have quite severe consequences. According to the FDA, 30% of medical device recalls in the U.S. are due to manufacturing defects, which often stem from human error. These recalls not only lead to financial losses for companies but also pose significant risks to patient safety.

Even though regulatory bodies such as the FDA and EMA impose strict guidelines on manufacturing practices, failure to comply with these regulations can result in fines, legal action, and irreparable damage to a company's reputation.

Given the high stakes, reducing error rates is not just a matter of business efficiency - it's a critical component of ensuring compliance and safety.

Training videos offer several advantages over traditional training methods, particularly in reducing error rates. Here's how:

Standardization of Training Content

Training videos provide a consistent, standardized form of instruction that ensures all employees receive the same information, regardless of when or where they undergo training. This standardization is crucial in a global industry where manufacturers may operate facilities in multiple countries, each with its own set of regulations and standards.

A study by the Journal of Business and Psychology found that employees trained through video are 50% more likely to retain information than those who receive in-person training or read training manuals. This increased retention leads to fewer errors, as employees are more likely to remember and correctly execute the procedures they have been trained to.

Employees trained through video are 50% more likely to retain information

Employees are 75% more likely to watch a video than to read documents

Knowledge retention by up to 60% more compared to other learning methods

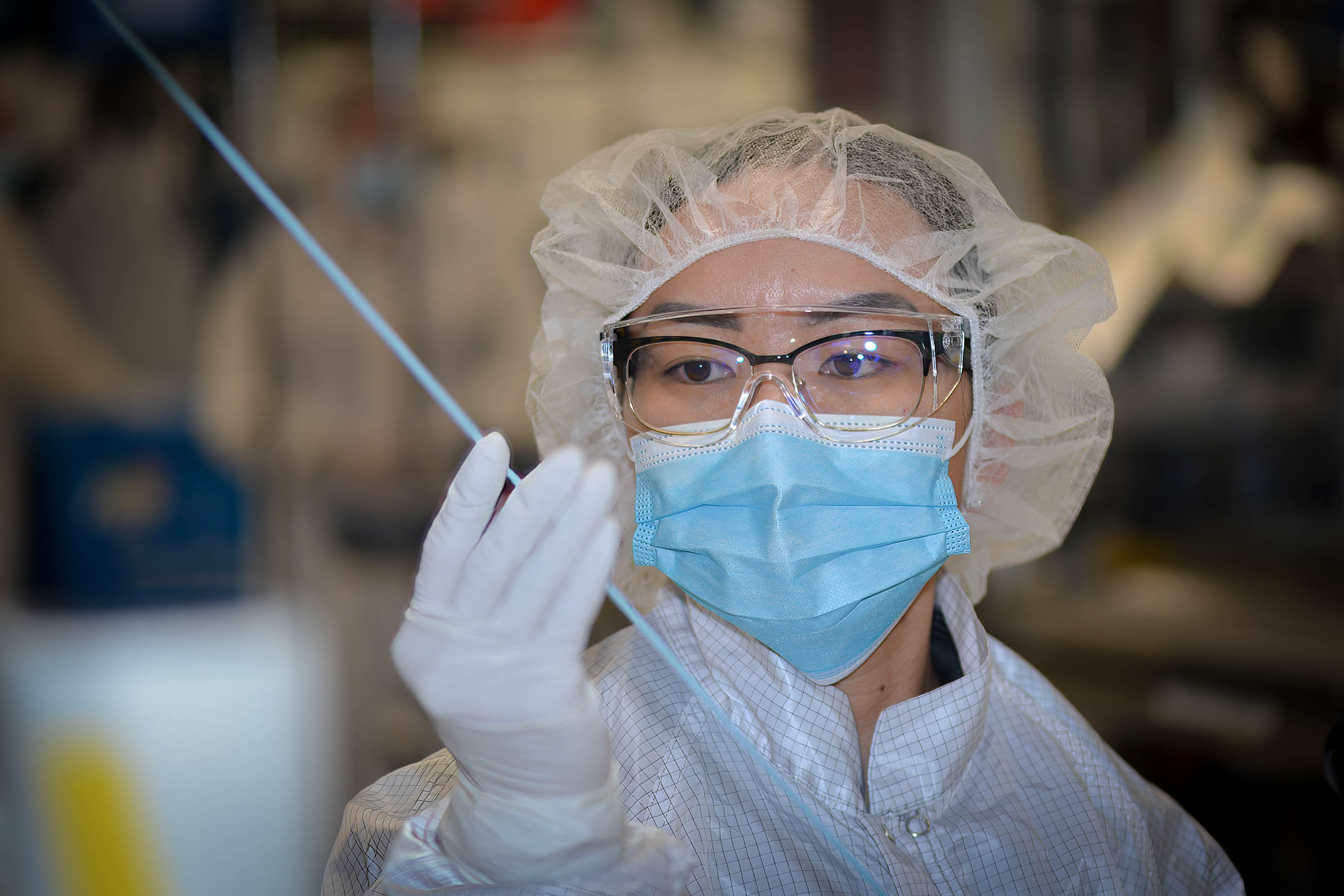

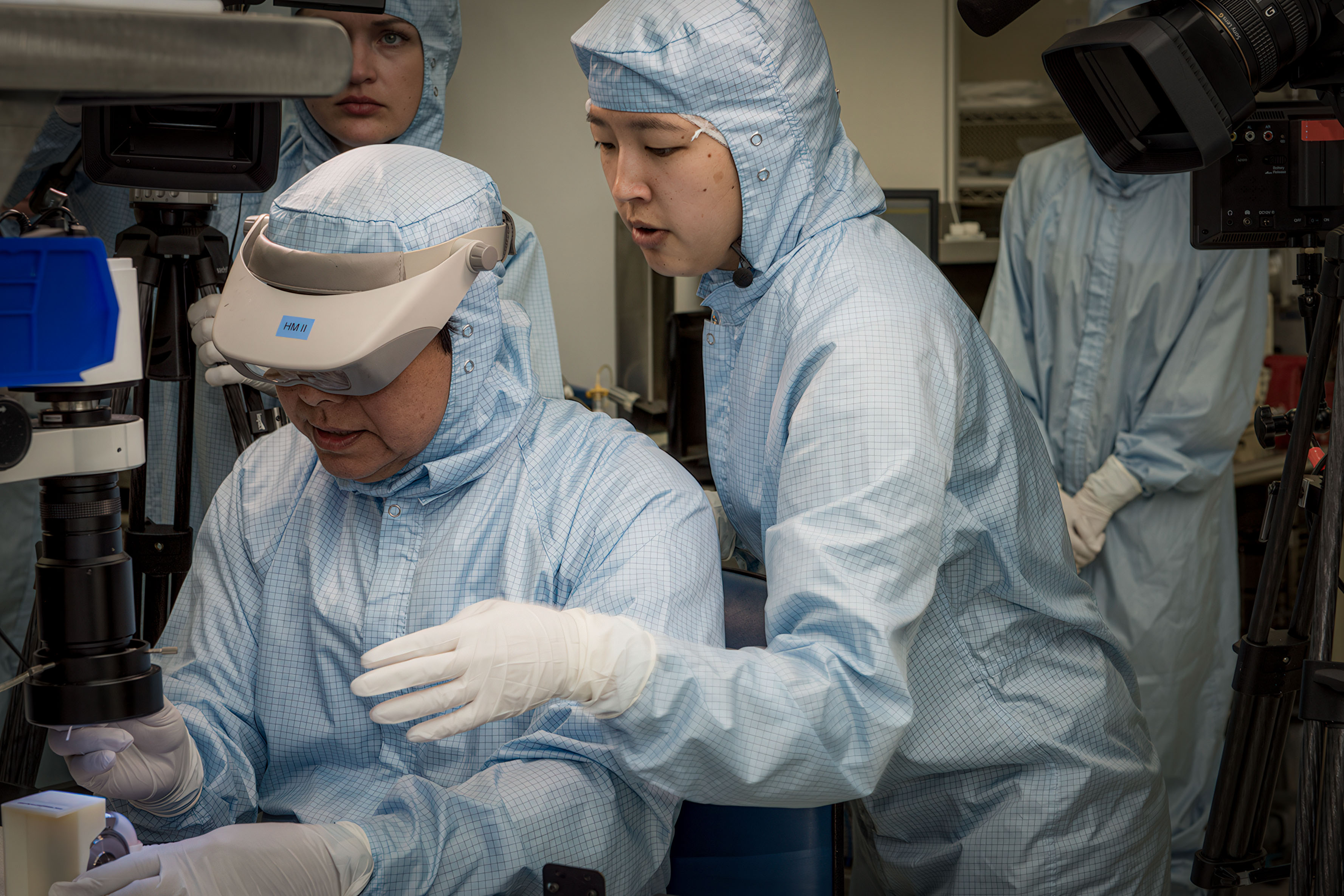

Visual and Practical Demonstrations

Medical device production often involves complex processes that are difficult to convey through text or stand-alone images. Training videos demonstrate these processes visually and dynamically, making it easier for employees to understand and replicate the required steps. For example, a video can show how to assemble a device, handle sensitive materials, or operate specialized machinery.

According to Forrester Research, employees are 75% more likely to watch a video than to read documents, emails, or web articles. This preference for video makes it an effective tool for conveying complex information in a clear and engaging way.

On-Demand Access and Repetition

One of the key benefits of using LightVision Media Group Content Delivery System (CDS) for training videos is that they can be accessed on-demand, any time from any device allowing employees to review the material as often as needed. This is particularly valuable in a production environment where procedures may change, or employees may need a refresher on certain tasks.

A report by the SAVO Group indicates that employees forget 65% of material covered in traditional training sessions within a week, and 90% within a month . By providing employees with the ability to revisit training videos, manufacturers can ensure that knowledge is reinforced and retained, leading to fewer errors on the production floor.

Information retention rate

covered by the traditional training

Interactive and Scenario-Based Learning

Modern training videos often incorporate interactive elements, such as quizzes, decision trees, and scenario-based learning. These features engage employees in active learning, requiring them to apply what they've learned in a simulated environment. This active engagement has improved knowledge retention by up to 60% compared to passive learning methods.

In the context of medical device production, interactive videos can simulate real-world scenarios, such as responding to a machine malfunction or correcting a manufacturing error (Rework Process). This hands-on practice helps employees develop the skills and confidence needed to perform their tasks accurately in a live production setting.

Conclusion

In an industry where precision and compliance are critical, reducing error rates is a top priority for medical device manufacturers. Training videos offer a powerful solution to this challenge, providing standardized, engaging, and accessible training that improves knowledge retention and reduces errors on the production floor.

By adopting training videos, medical device manufacturers can significantly reduce errors, ensuring that their products meet the highest standards of quality and safety.

As the medical device industry continues to grow and evolve, companies that invest in video-based training will be better positioned to maintain high standards of quality and compliance, ultimately leading to safer products and a stronger bottom line.