In today’s highly competitive manufacturing landscape, maintaining superior quality is paramount. As manufacturers strive to produce high-quality products consistently, traditional quality control methods are evolving to incorporate advanced technologies. Among these, visual media tools have become indispensable in the quality control process. This article explores how these technologies enhance manufacturing quality control and drive industry excellence.

Historically, quality control in manufacturing relied heavily on manual inspections and static measurements. While these methods served their purpose, they often fell short in detecting subtle defects or issues that could compromise product integrity. Visualization of inspection methods through video and 3D animation provides deeper dynamical insights, improves accuracy, and enables proactive problem-solving.

LightVision Media Group has a decade of experience working with engineering and QI teams to provide vital support in a wide range of projects:

- Process visualization

- POC endeavors

- Inspection Methods Validation

- Digitizing Non-Conformance libraries

and many more.

Video Technology

A Window into Real-Time Quality Assurance

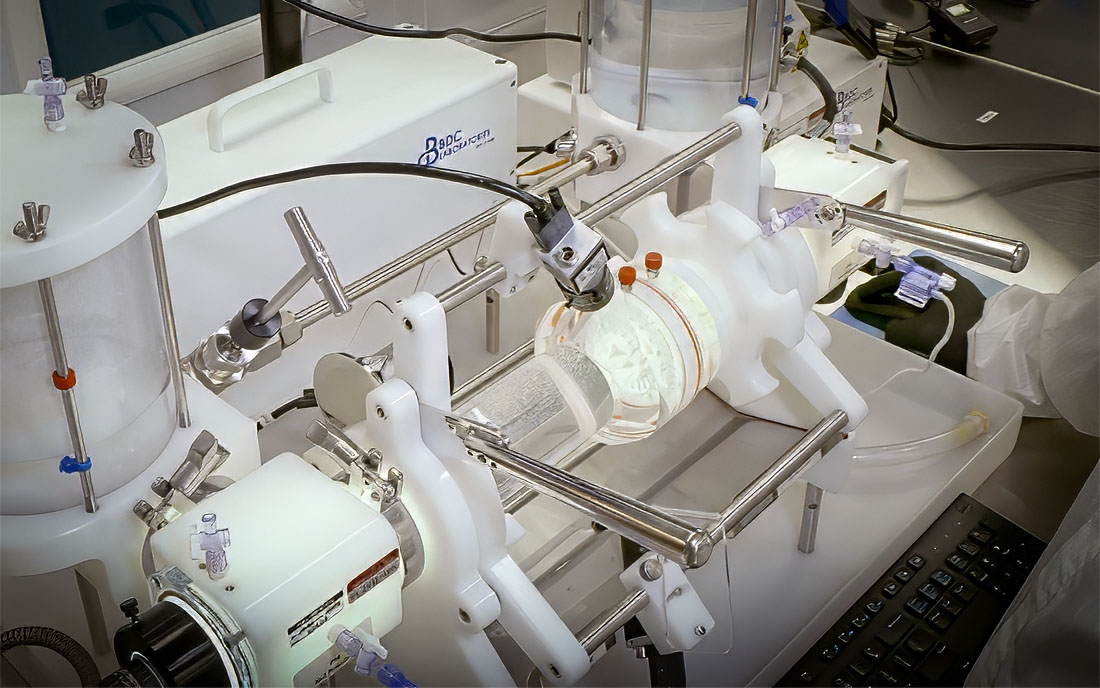

Monitoring and Analysis

Video technology allows for analysis of the manufacturing process. High-definition video at various stages of the production process enables quality control teams to observe processes as they are trained and performed on the production floor. This capability is crucial for identifying and addressing defects and procedure faults at the early stages of the product’s lifecycle.

Enhanced Communication

Video recordings facilitate better communication among team members and between different departments. For instance, if a quality control issue is identified, a video can be shared with the production team to illustrate the problem clearly. This visual aid helps in faster and more effective resolution of issues, ensuring that corrective actions are taken promptly.

Documentation and Inspection Alignment

Videos provide a valuable resource for documenting quality control procedures and manufacturing standards. This documentation can be used for training new quality team members, ensuring that they understand the QA benchmarks and procedures. Additionally, video can serve as a reference for troubleshooting recurring issues, thereby streamlining the problem-solving process.

3D Animation

Visualizing and Simulating Complex Processes

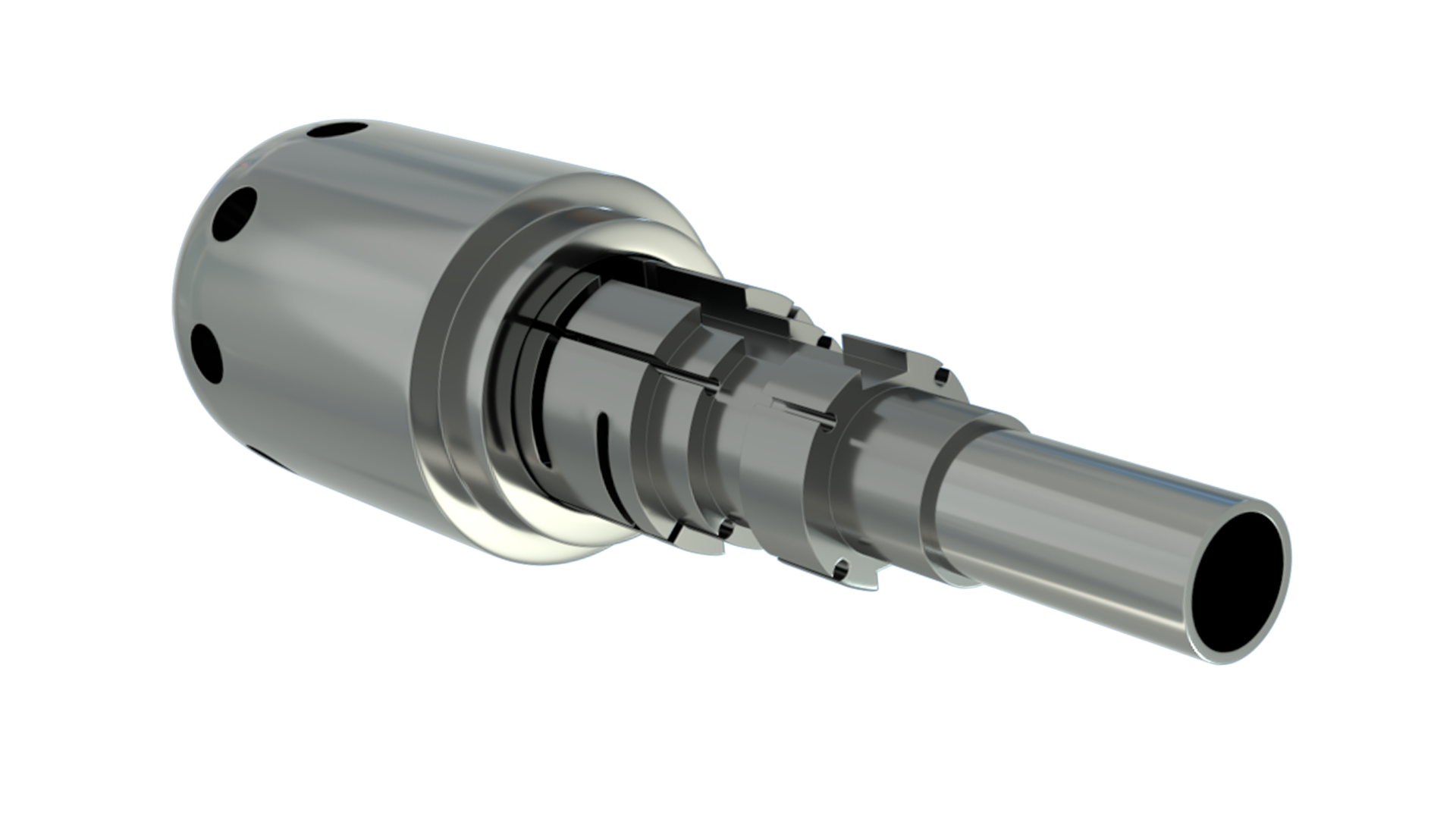

Detailed Process Simulation

3D animation allows manufacturers to create detailed simulations of manufacturing processes. These animations can visualize complex machinery, workflows, and assembly procedures, offering a clear understanding of how various components interact in the production workflow. This visualization often reveals potential quality control issues that might not be apparent in a static environment.

Design and Prototype Testing

Before committing to full-scale production, manufacturers can use 3D animation to test and refine product designs. By simulating different scenarios and stress tests, manufacturers can identify design flaws and quality issues early in the development phase. This proactive approach reduces the risk of costly revisions and ensures that only high-quality designs reach production. POC visualizations also help to present concepts to key stakeholders, helping engineering teams gain necessary traction and support.

Improved Quality Assurance

3D animations can also be used to create detailed quality assurance checklists and procedures. These animations guide quality control teams through each step of the inspection process, ensuring that all aspects of the product are thoroughly evaluated. This consistency in evaluation helps in maintaining high standards across the production line.

Microscope Video

Precision in Detail

High-Resolution Inspection

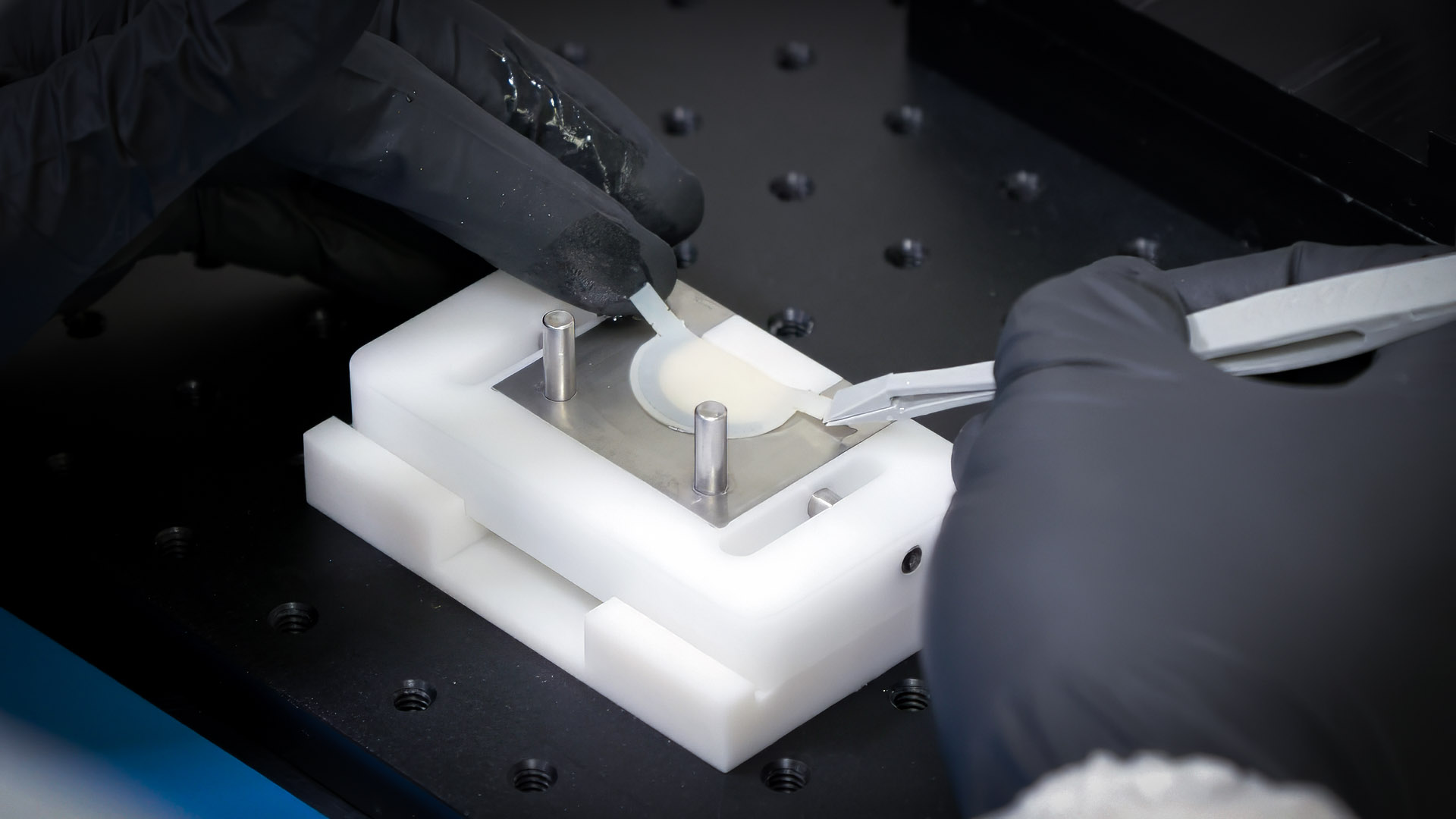

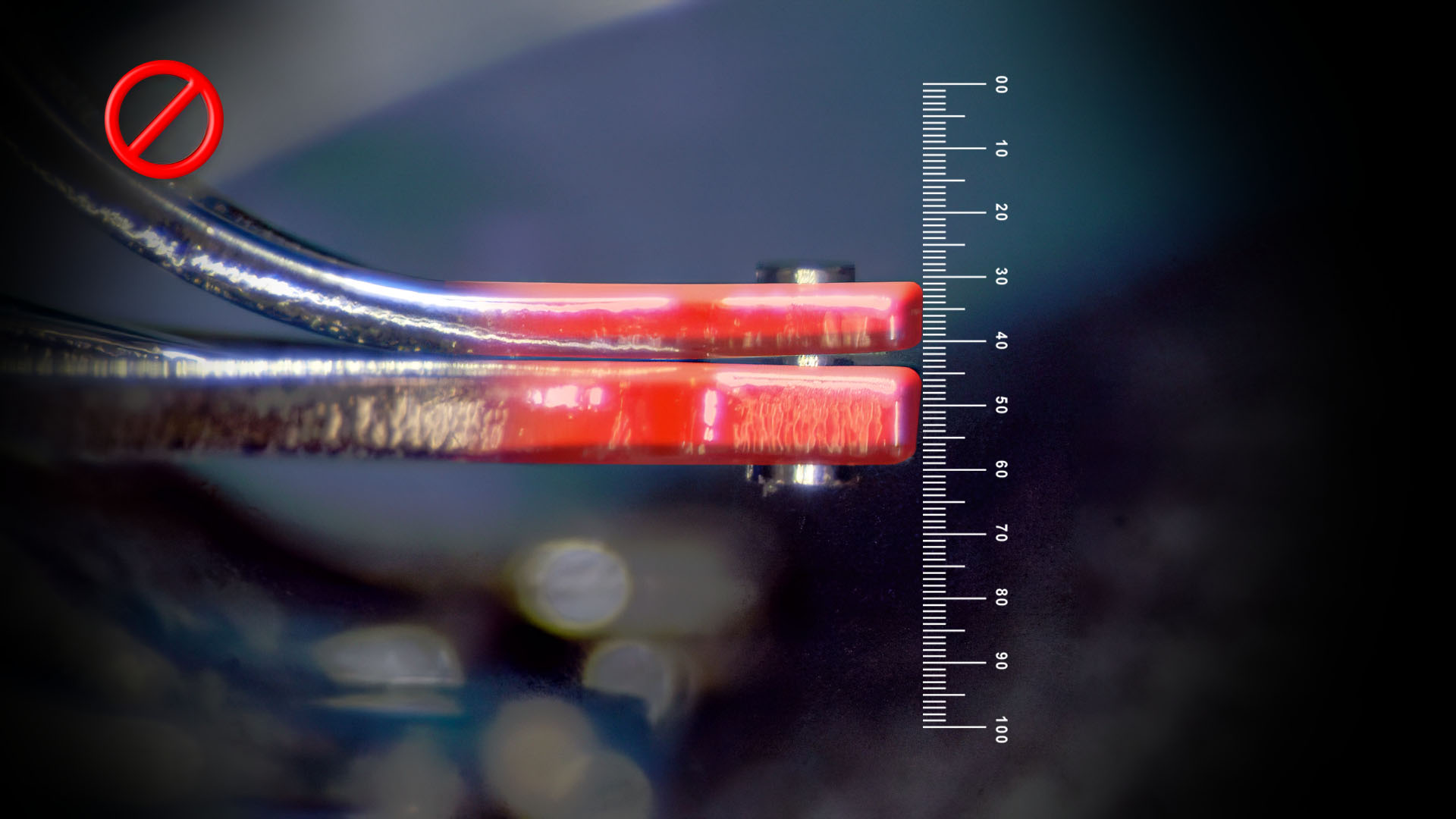

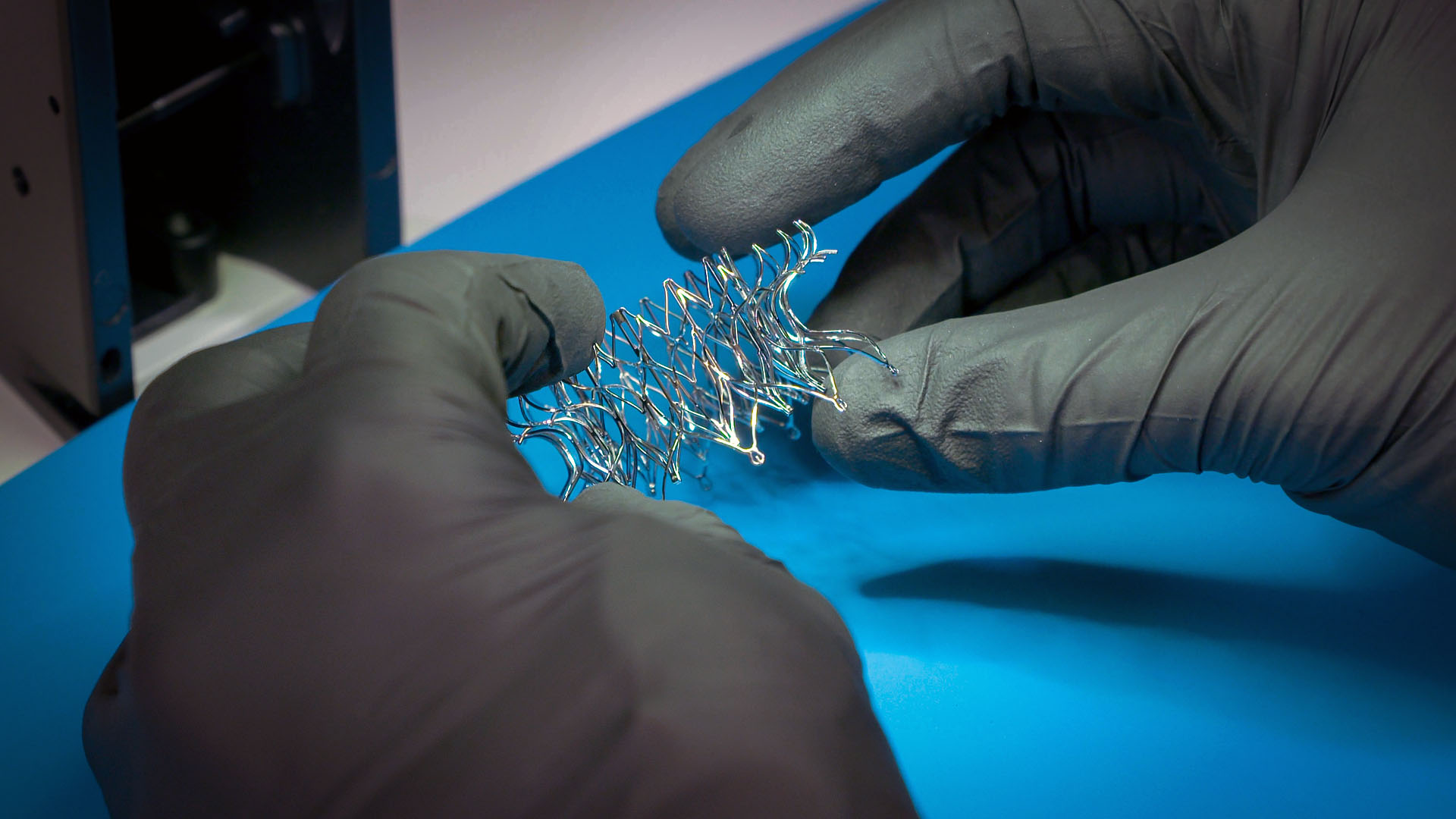

Microscope video technology provides high-resolution imaging that reveals minute details often missed by the naked eye. This technology is essential for inspecting intricate components and detecting micro-defects that could impact the product's performance or longevity. For industries such as medical device manufacturing, electronics, and aerospace, where precision is critical, microscope video ensures that every detail meets stringent quality standards.

Detailed Defect Analysis

With microscope video, quality control teams can capture and analyze defects in high detail. This capability allows for precise identification of the root cause of defects, whether they are related to material flaws/handling (organic tissue), manufacturing processes, or assembly errors. Understanding the nature of defects in detail helps in implementing targeted corrective actions.

Long-Term Quality Monitoring

Microscope videos can be used to monitor changes in materials or components over time. By analyzing time-lapse footage, quality control teams can observe how materials behave under different conditions, providing insights into their long-term reliability and performance. This long-term monitoring helps in identifying potential issues that might arise during the product’s lifecycle.

Conclusion

The integration of video technology, 3D animation, and microscope video into the quality control process has transformed manufacturing. These advanced tools enhance real-time monitoring, detailed analysis, and process simulation, leading to more accurate and efficient quality control. As manufacturers continue to seek ways to improve product quality and operational efficiency, embracing these technologies will be key to staying competitive and ensuring excellence in production.

In a world where precision and quality are non-negotiable, leveraging these technological advancements is not just a choice but a necessity.

By incorporating video, 3D animation, and microscope video into quality control practices, manufacturers can achieve higher standards of excellence and drive success in an increasingly competitive market.